The physics of deforming metals

Plastic deformation of a metal introduces trillions of defects - dislocations – which self-organize in patterns on many length scales. Quite remarkably no material models exist that can predict how this organization will take place. Dislocation interaction is the origin of significant metal strengthening but due to lack of knowledge of the self-organization, models of metal strength are phenomenological. The group has built the world's first multiscale X-ray microscope – at ESRF in France - with this issue as the present primary science case. Using the microscope we have visualized dislocations and dislocation motion deeply embedded in a 1 mm thick sample. Together with 30 years of modeling experience this opens up for a paradigm shift, where metallurgy becomes based on first principles. This work is the foundation of a new ERC Advanced grant, Physics of Metal Plasticity, starting 1/10 2020, where the 3D experimental movies will be integrated with 3D dislocation dynamics simulations and crystal plasticity simulations – in collaboration with Purdue University. A physics based model of metal strength would have a major impact on the metal forming industry and be a spectacular demonstration of how the "material design by computing" vision of SOLID can be implemented.

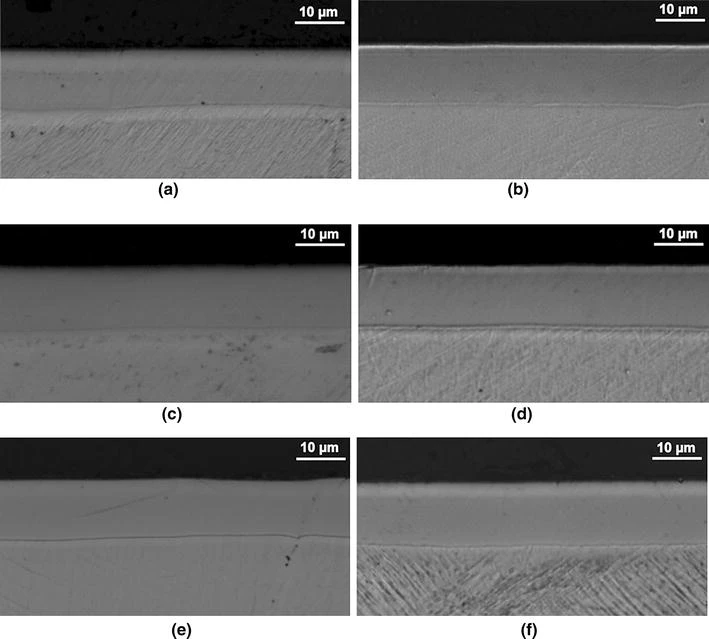

Visual representation of the plastic deformation on stainless steel is shown on the figure below. It is part of an article called Low-Temperature Nitriding of Deformed Austenitic Stainless Steels with Various Nitrogen Contents Obtained by Prior High-Temperature Solution Nitriding by Federico Bottoli, Grethe Winther, Thomas Lundin Christiansen, Kristian Vinter Dahl, Marcel A. J. Somers.