Multi scale modelling and simulation

The multi-scale nature of the experimental techniques within SOLID, which in many cases also visualizes the dynamics, produces unique data sets. The new discoveries will guide development of multi-scale models with the ultimate aim of designing new materials with specific properties by computer simulations instead of trial-and-error in the laboratory. In many cases, such new materials are essential to solve the major societal problems of today, e.g. within the climate, health and energy sectors. Modelling within SOLID spans wide from e.g. thermodynamic calculations over the dynamics and accumulation of defects at the nanoscale to flow in porous materials. A better understanding of fundamental processes inside materials subjected to realistic external stimuli for example of thermal, chemical or mechanical origin, will enable a new generation of material models capable of mechanistic predictions of changes in the material structures and properties.

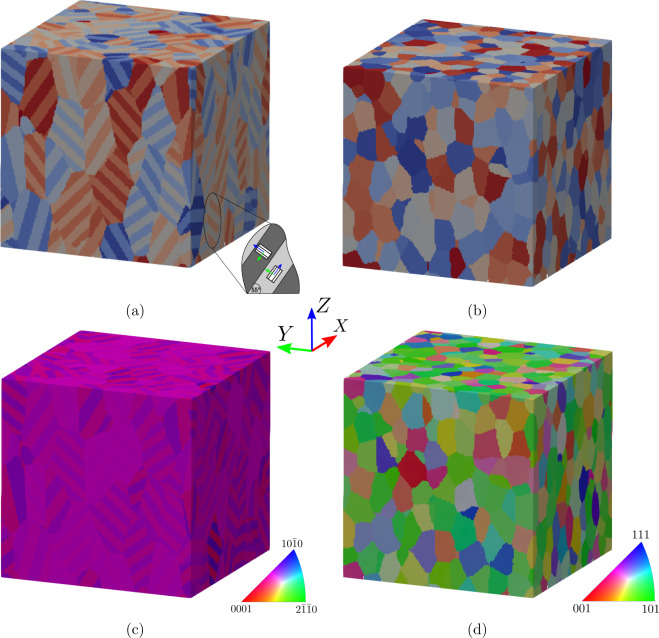

Example of multi scale modelling and simulation, done from SOLID is presented on the upper figure. It is from the paper Anisotropic yield surfaces of additively manufactured metals simulated with crystal plasticity from K. Somlo, B.H. Frodal, C.V. Funch, K. Poulios, G. Winther, O.S. Hopperstad, T. Børvik, C.F. Niordson. It shows generated representative volume elements (RVEs) for Ti-6Al-4V titanium alloy and stainless steel (316L) as well as inverse pole figure (IPF) maps.